Fast and precise control valve is better, it saves money.

Stability in regulation requires a fast valve

A control valve will oscillate if:

- hard point is on stroke.

-

valve is slower than the process. Valve must be faster than stability criterion (generally 3s per inch)

- set point enters the "dead zone"

- flow shows a gap between two following set point

oscillations destroy valves and process

MPSA solutions :

- MPSA valves have , by design no hard point, motion is continuous and effort is linear

- MPSA valve are able to perform full stroke in 0.35s per inch . and 1.5s per inch with 180w electrical motorization (None of our competitors can match us)

-

MPSA control stroke is from 1% up to 100%. MPSA valves have no "dead zone "

-

MPSA flow control is continuous and linear. Lineariy allows an easy and accurate flow control on the whole valve stroke. MPSA valves are , by design, physichally linear from 1 % up to 100% , without electronic artifice .

Better control flow is a better process exploitation and installation is protected

Fast on/off valve is better, where are benefits?

DN500 pneumatique Vannes HIPPS on/off, Comparons les

HIPPS ball valves

Closing time "announced" at 3s

HIPPS axial valves

Closing time "announced" at 2s

MPSA VHIPPS valves

Closing time TESTED at 0.3s

None of our competitors can match MPSA

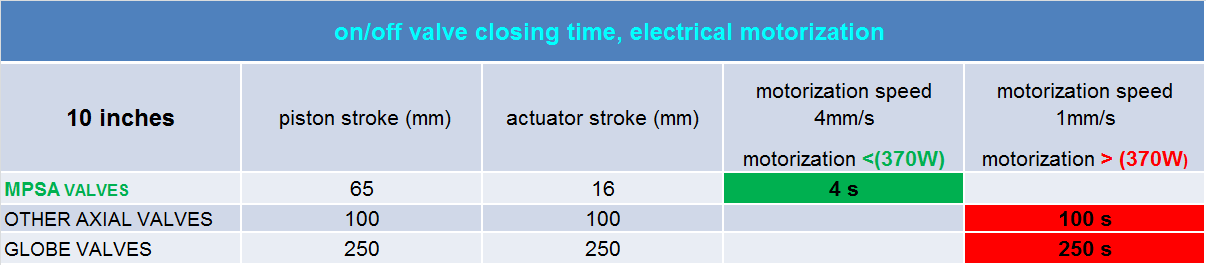

Electrical motorized on/off valves to be compared